Scientific blog post about the environmental impact of clothing manufacturing in light of the upcoming Black Friday

This blog post is written in advance to the upcoming Black Friday. This blog is scientifically written and has the purpose to make readers aware of the processes involved in the making of clothes. It is purely informative and does not pass judgment on your consumption pattern. The blog is divided in ‘Life cycle of clothing – introduction’ & ‘Black Friday’ & ‘sustainable choices’. At the end, extra information about the in depth wet processing steps will be given as a further read.

Life cycle of clothing – introduction

Wouldn’t it be weird if you saw someone walking across the street without any clothing on? In the world we live today, it is very unlikely to have that happen to you. Your friends, your family, your neighbor and in some cases even your dogs, are all comfortably wrapped in clothing. It is something we don’t think about for a second, when you wake up, the first thing you do is dress yourself. Clothes, in any form whatsoever, are everywhere around us, from the moment you were born. That is because there is a general consensus that clothing is a fundamental necessity that every human should have access to, just like food. However, there is a stark contrast between the two in terms of global abundancy. Globally, there is a food shortage, but when it comes to clothing, there is a substantial excess.

Due to the poor preservation characteristics of the earliest clothes, It’s hard to say when exactly our ancestors first started wearing clothes. A estimation is set around 70.000 years ago (Balter, 2009). The first form of clothing originates form animal skin, with the purpose of protecting humans against the shivering coldness of the ice ages. Only till around 30.000-40.000 years ago, humans acquired the skill to weave plant fibers into textiles and even dyed clothes were found (Balter, 2009). Lets assume that no fashion influencers were around at that time and clothes solely served the purpose of protection and camouflage.

Throughout history, clothes became much more than that, with changing emphasis on various aspects such as hierarchical position in society, distinction in culture, profession, nationality, religion and human identity… The anthropological study of historical clothes can even provide us more insight about the social, political and economical history of a particular region (Hansen, 2004).

The base of all clothing is textile, but what is it exactly? The term ‘textile’ refers to products consisting of multiple fibers or yarn, where yarn is made by spinning either natural fibers (cotton, silk and wool) or manufactured fibers (polyester and acrylic). From this, fabrics are made trough a process of weaving, knitting, spinning, slashing or twisting (Sinclair, 2015 & Farhana et al., 2022). Each of these processing steps come with certain energy costs, where the dominant energy sources are electricity and fossil fuels (Farhana et al., 2022). ‘Wet processing’ is the next step in the manufacturing of an end product. Depending on its purpose, different treatments are followed. Examples include dyeing, bleaching, washing or addition of water repellent/fire resistant surfactants. In these processing steps, huge amounts of water are needed in the form of steam. To create this form of thermal energy, fossil fuels are used to heat the water (Farhana et al., 2022). Eventually, it was found that the footwear and garment industry combined are responsible for 8% of global greenhouse gas emissions.

Besides, a lot of polluted wastewater is discharged to natural systems during these wet steps. Countries with bad wastewater treatment can be heavily impacted by the pollution, with consequences on ecosystems but also human health. For example, in India, 10-25% of textile dyes and chemicals are found in the wastewater with 2-20% of dyes that reach the environmental systems as aqueous effluents (Farhana et al., 2022).

After manufacturing, clothing still need to reach the consumers trough transport of the product. Depending on supply and demand, countries have a dynamic import and export of textile products. The global market value of the textile sector in the year 2022 was estimated at 1 trillion EUR. In 2022 more than 80 billion pieces of cloth were produced, this makes apparel the biggest consumer of textile (Farhana et al., 2022) with China having the largest fashion market since 2019. The US has the second largest (Wang et al., 2022).

Due to globalization and the removal of world trade quotas on textile in 2005, the import and export of clothes across the globe was amplified. For the EU, the biggest import of textile is coming from China, India and Turkey. These countries are responsible for half of the EU textile import, with an emission of around 9.000 Kt of CO2 (Valodka et al., 2020). Moreover, it is seen that developed countries move the production of clothes to undeveloped countries with less restrictions and above all, a lower production cost (Valodka et al., 2020). In that way, developed countries benefit from the low cost manufacturing of clothes in developing countries, with the last one bearing the cost of carbon emission and air/water/soil pollution. Besides, developing countries such as India, Mexico, Bangladesh, China, etc experience an increased demand for apparel themselves, caused by the ongoing growth of their population. Although it is seen that the textile sector is closely linked to the economic welfare of developing countries (among others by presenting more employment opportunities), the threats it poses to the local and global environment and the well-being of the workers cannot be neglected. (Farhana et al., 2022).

You might think that once the product reaches the consumer, no additional pollution will be caused. However, every time clothes get washed in washing machines, microplastics are released. Every time a synthetic garment is washed, it releases tiny plastic microfibers into the water. The textiles and fashion waste is responsible for 9% of annual microplastic pollution added to our oceans.

Also, after usage, clothing can be either discarded as waste in landfills, incinerated, introduced into a circular market or utilized for textile recycling. Reuse and recycle are among the best options for disposal of your clothing. When the product is discarded as trash, the options are to degrade the separated clothing (based on certain traits of the product) into biofuels or incinerate it with a low margin of energy production. The least favorable option is to put the clothing into landfills. Which option is chosen depends on the consumer of the product. However, sadly 87% of the materials and fibers used to make clothing will end up in either incinerators or landfills. The world produces 92 million tons of textile waste every year, with each second, a garbage truck loaded with clothes being dumped into landfills (Chen et al., 2021). This has led to clothing and textiles making up at least 7% of the total amount of waste in global landfill space.

Black Friday

Black Friday was initially invented in the US as a post-Thanksgiving sale, it started in the mid-1960s. However, the concept rapidly blew over to developed countries in Europe and became an annual habit across the globe. Now, according to GlobalData, shoppers spend nearly €10.5 billion in four days during the 2021 Black Friday to Cyber Monday period. This still is a substantial increase on the €9 billion spent in 2020. Products that are most frequently bought (every year again) are clothing and electronics. Products that have an increasing popularity over the years are smart home electronics, exercise equipment and audio equipment.

The in store purchases increase by a vast amount, but the online sales increase even more. It was seen that Amazon sales during this period rose with at least 175% for the UK, Spain and France and going up to 400% for Italy and Germany. Amazon even had to implement a new temporary hiring system where they hire 20.000 temporary staff to handle the huge online consumer demand. However, this shift to online shopping is not a pleasant thing for the environment. The Conservation journal stated in 2021 that carbon emission from buying a clothing product online can be four times that of buying the same item in store. The high return rates of online bought clothing items contributes to this. However, other research contradicts this and state that physical stores that ship their clothing to their online costumers have a CO2 reduction by 20-90% in comparison to the emission involved in in-store purchases (Shahmohammadi et al., 2020). The reasoning behind this is the lesser transport of costumers to the store, and the scenario of customers driving to the store and leaving without making a purchase doesn’t apply to online purchases. Nonetheless I find a reduction of 90% hard to believe… but further on it was stated that the stochastic model used in this research had certain limitations. For example regions where the costumers often walk or cycle to shops, don’t have a difference in CO2 emission (Shahmohammadi et al., 2020). This is the case for China, the largest fashion market in the world.

You know about the option of fast delivery right? By paying a little more, you can completely disrupt the transport chain! Suppliers change the order of parcel pick-up and delivery, and this comes at the expense of its efficiency with more CO2 emission as a consequence (Shahmohammadi et al., 2020). That makes me think, how can we make consumers aware of the environmental impact of fast delivery? Just add information on the CO2 emission of every delivery option right? In my opinion, that should be reasonable for big retailers like Amazon or closer to home bol.com.

💡The green house gas emission for in store purchases can be reduced by simple using a more sustainable transport mode or by strategically planning your shopping trips. An obvious example is combining visits to other stores so that you don’t need to visit them separately on other days. Also an option is to go shopping when coming home from work, in this way you aligning store visits with your daily activities that are located in the same direction.

❌ Black Friday is a week to forget for small and local business. They are often at a disadvantage because they are not able to compete with the discounts given by the large global retailers. Shopping locally made products is beneficial for the carbon footprint as well as the local economy.

Sustainable choices

As became clear from the introduction, you should consider all of the following aspects in the production of clothing: (1) choice of raw fiber material (2) processing of fiber into garment (3) end of life treatment. This makes it very hard to tell which type of clothing is more sustainable.

► (1) Choice of raw material. You can make use of bio-based fibers that grow in nature, such as cotton. But that does not mean that the eventual end product is bio degradable. It is likely treated with microplastics and toxic dyes in further processing steps. Besides, to grow cotton, a huge amount of water is needed and the monoculture plants are treated with unbelievable amounts of pesticide. So this ‘bio-based’ raw material could be misleading if not sustainably harvested or processed…

💡Organic cotton, in contrast to ‘cotton’, is a sustainable fiber with low impact on the environment. Natural fertilizers, biological pest control methods rather than synthetic pesticides, and crop rotation to maintain soil fertility are implemented to grow organic cotton. Avoid cotton and go for organic cotton! Other natural sustainable fibers are recycled cotton, hemp, linen, bamboo linen, cork. However, fibers don’t need to be ‘natural’ for them to be sustainable. Lyocell for example is a synthetic fiber that is manufactured from biomaterial (woodpulp) with a good environmental footprint due to its biodegradability and the high water recycling capacities during the process with less pollutants used.

❌ Polyester & Nylon; fibers to avoid. Both are synthetic fibers derived from a non-renewable resource (petroleum → Polyester | petrochemicals → Nylon). Its production involves the use of chemicals, and the process can contribute to air and water pollution. Additionally, both are not biodegradable, leading to concerns about its long-term environmental impact. However, some parts of the garments can be recycled in specialized facilities and further efforts are being made.

► (2) Processing of fiber into garments. This includes wet processing steps such as desizing, bleaching, dyeing, finishing, etc that have huge amounts of water consumption, energy use, carbon emission, chemical pollution… However, a lot of advancements have been made to reduce the above mentioned negative impacts. More on this can be found in the last chapter of this blog but for now lets focus on an interesting company called PureDenim.

💡 Jeans are among the most environmental unfriendly products due to its high water consumption and consecutively bleaching and dyeing treatments. The labor intensive processing and involved chemicals are causing harm to the employees and environment. However PureDennim synthesized a sustainable dye called Smart Indigo. This dye needs significantly less water to be fixed to garments, also chemical products to facilitate fixation are excluded. This reduced water and chemical compound use leads to energy saving and less pollution. However, the sold jeans are quite expensive…

💡A cheap and environmentally friendly alternative is buying a pair of second hand jeans!

► (3) End of life treatment. As previously mentioned, the consumer is in charge of the disposal of their old clothes. However, the product itself can have traits that make recycling of the fabric more or less easy to recycle. Garment recycling can be divided into different categories; upcycling (value-added transformations) or downcycling (value-decreased transformations) or breaking it back down to small fiber fragments to re-use in new clothing or other textile products. This destruction can be done mechanically, chemically, or thermally (Goldsmith, 2012; Lewis, 2015).

💡Recycling and reusing your used clothing is the most sustainable option. An interesting brand to mention is Patagonia because it’s one of the first and most successful brands to turn PET bottles into fleeces on a large scale. They kicked off this initiative in 1993.

❌ Landfills are the worst destination for discarded clothing. They take up a lot of land, cause damage to vegetation, have unpleasant odours, cause ground water and air pollution, release methane and carbon dioxide gas during degradation by bacteria (El-Fadel et al., 1997).

Over the years, the textile market has become increasingly more regulated. Now, you can find labels on manufactured pieces that provide an indication or score regarding the sustainability of a product. There are various labels that exist, a small list is provided here with a quota for what they stand for.

“Cradle to Cradle certification provides a framework for product optimization based on the principles of designing with safe and healthy materials, using clean renewable energy and water, celebrating diversity, and eliminating the concept of waste”

“The Global Organic Textile Standard (GOTS) was developed by leading standard setters to define world-wide recognised requirements for organic textiles.”

“ The OEKO TEX® MADE IN GREEN label also reassures consumers that the textile or leather product is made of materials that have been tested for harmful substances.”

“The EU Ecolabel on clothing and textile products offers a reliable way of identifying high performing environmentally friendly textile and footwear products that are available on the European market.”

EXTRA – The most polluting steps: wet processing (desizing, bleaching, dyeing, finishing, etc)

After spinning the raw materials into yarn and eventually fabric, the wet processing steps follow. The textile is subjected to a whole series of treatments going from desizing – scouring – bleaching – dyeing & printing – finishing etc… The name indicates the main resource in these steps; water.

Since untreated fabrics don’t fixate dyes efficiently, a desizing is conducted with use of oxidative or acidic desizing agents such as poly vinyl alcohols. Furthermore, impurities of the fabric (dirt, gum, waxes) are removed in an alkaline high temperature environment (Gulzar et al., 2018). In both processes, the targeted compounds are turned into water soluble compounds that end up as effluents in wastewater. Then a bleaching step is done to achieve a desired whiteness of the fabric. Bleaching steps involve oxidative agents like NaClO2, NaClO, and H2O2 (Gulzar et al., 2018) and again alkaline high temperature environments are required. Further on, garments are treated with dyes and salts to give textile fibers the desired color. Mostly synthetic dyes with toxic traits and low to non biodegradable capacity are used rather than natural dyes. Bio based dyes can come from plants, animals or microbes (Gulzar et al., 2018). The dye of choice depends on the used raw material and the properties of the dyes itself. A classification can be made; (1) reactive dyes that covalently bind with functional groups of the fabric, (2) chemical dyes that are in need of a chemical reaction to bind to fabric, (3) disperse dyes with low water solubility (highly carcinogenic) (Gulzar et al., 2018). In the finishing steps, even other chemicals are applied such as softeners or antimicrobial agents to protect silk, wool and cotton from fungi and bacteria. For a long time, triclosan was used as an antimicrobial, but this compound degrades into a highly toxic polychlorinated compound upon interaction with sunlight.

In total, textile processing units make use of 8.000 different chemicals, with dyes being the most polluting components in the wet processing due to its abundance and application method (Gulzar et al., 2018). After application of the dyes, a washing step is done to get rid of the unfixed dyes. As a result of the poor fixation capacity of traditional dyes, more than 30% are not bound to fabric and find its way into the environment (Gulzar et al., 2018). Yearly, up to 200.000 tons of dyes reach natural systems through wastewater drainage (Farhana et al., 2022).

Treatment of wastewater is dependent on the concentration and nature of the contaminants and future application of the wastewater. When only mildly contaminated, wastewater effluents can be combined with process water to be reused in other processes that don’t require high quality water. When highly contaminated, wastewater is subjected to brackish water reverse osmosis (BWRO), nanofiltration to segregate the different components (salts, organic material, chemical compounds, etc.), anaerobic/aerobic biological treatment or advanced oxidation (Ozturk et al., 2015). An even better way to reduces discharge of contaminated wastewater in groundwater and river systems is to reduce the initial contamination at its source, by making use of sustainable dyes.

Besides the pollution that are caused by the dyeing process, a very high amount of (hot) water is demanded in these wet processing steps. Up to 80% of water usage in the production of clothes originates from wet processing steps, with dyeing needing the most. The amount of water consumption is dependent on the used dye, fiber and dyeing mill protocol with an estimation for multiple Turkish mills of 46-74 L H2O/kg product and a production of 56L/kg product wastewater (Ozturk et al., 2015). Other sources come up with a consumption of 50-100 L H2O/kg (Gulzar et al., 2018). To reduce water consumption, obvious steps can be implemented such as increasing the efficiency of washing units and machinery, wastewater treatment/recovery and optimizing dyeing/washing/finishing protocols. Research on a dyeing mill in Turkey found out that by making use of a counter-current washing system and automatic shut-off valves, up to 50% of process water could be saved (Ozturk et al., 2015).

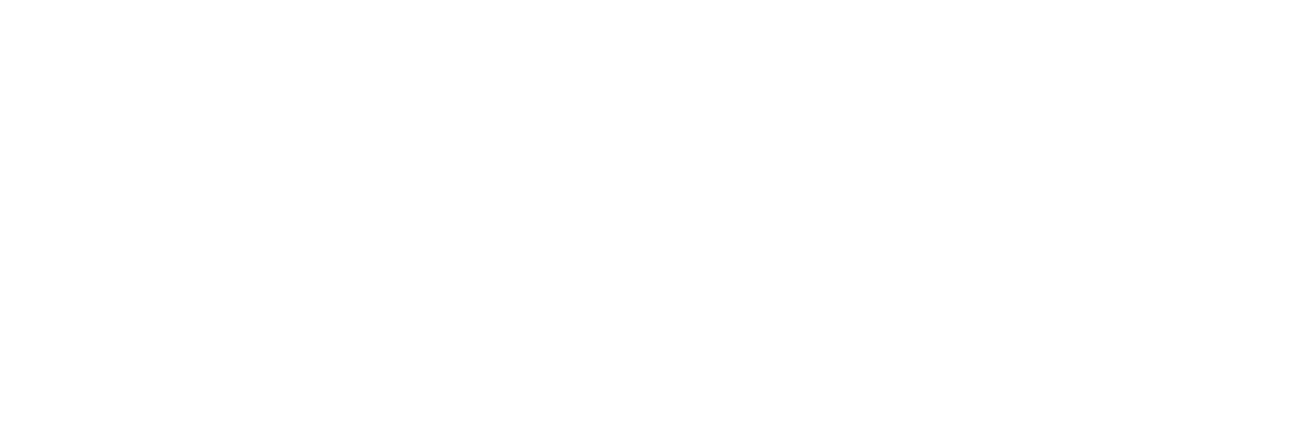

In addition to water pollution, wet processing is the biggest consumer of energy throughout the life cycle of a garment. This is because dyeing, finishing, bleaching and softening all require substantial amounts of steam. Fossil fuels are the primary energy source to generate this steam, with coal, oil and liquefied petroleum gas being the most popular sources (Gulzar et al., 2018). The energy consumption in textile plants is estimated at 37-116 MJ/kg product, with the shares being shown in table 1 (Gulzar et al., 2018; Ozturk et al., 2015). The high energy demand is met with combustion of fossil fuels, leading to emission of CO2, flue gasses and volatile organics (hydrocarbons, formaldehyde, dichlorobenzene, chlorofluorocarbons, methyl naphthalene, etc) (Ozturk et al., 2015). This makes the wet processing the biggest contributor of CO2 emission in the lifecycle of garments, with an estimated emission of 3.5 g CO2/kg product. Annually, the textile industry is responsible for 10% of the total CO2 emission (Farhana et al., 2022).

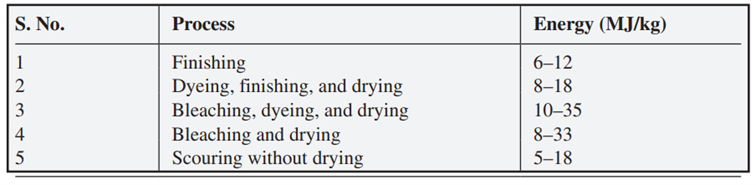

By implementing ‘best available techniques’ (BAT) for energy recovery, it is possible to reduce energy consumption by 20% – 70%. A possibility is heat recovery from hot wastewater and flue gasses. Also implementation of solar thermal energy in heating systems could be a sustainable alternative and it is a good investment economically and ecologically. A study on two Turkish heating systems by Muneer et al in 2008, concluded that the economic payback period aims at 6 years. Substitution of traditional fossil fuels with biomass such as pine woodchips and wood pellets can save energy use up to 27% and 18% respectively and are a cheaper way of steam production. More emerging technologies and their benefits can be found in table2(Chen et al., 2021).

Making use of multifunctional dyes with better fixation properties forms a promising solution to both tackle energy use and wastewater pollution. These dyes can be fixed to the garment at low water temperatures, with significantly less dependence on additive salts. Examples are Reactive Yellow 2, Reactive Orange 16, Reactive Blue 4, Cl Direct Blue, etc (Gulzar et al., 2018). Combing this technique with ionic liquids as a solvent instead of water or making use of plasma technology to fix dyes, drastically reduces energy consumption as a direct result of decreased water consumption. A key message here is that a lower need for water simultaneously results in a decreased energy consumption to form hot water/steam and less wastewater effluents (Nidhi et al., 2016).