Note: This is an updated version of the Analysis & Policy Brief that was first published on the website of the University of Antwerp on 1 July 2020.

In response to growing international concerns over mineral extraction and trade contributing to human rights violations and conflict financing, recent US (Dodd-Frank) and EU legislations have focused on transparency and due diligence in mineral supply chains. Simply put, companies must provide information on their supply chains and demonstrate that they identify and act upon risks. As such, “companies are increasingly held morally, politically and legally accountable for their activities, or those of their suppliers, abroad”. Our broader research project, of which this Analysis & Policy Brief is part, focuses on accountability in non-state supply chain regulation (how can private actors be held to account?). This Brief reports on a case study of the most widely used traceability and due diligence programme, the International Tin Supply Chain Initiative’s (ITSCI) Programme for Responsible Mineral Supply Chains, as it is implemented in Rwanda (where the first author conducted field research in August-October 2019). We find that private actors can indeed be held to account, if four conditions are met: the programme should provide clear and timely information; high-quality and frequent monitoring should be ensured; there should be a possibility of imposing credible sanctions; and the governance of the programme should act in the public interest.

Context: due diligence and non-state supply chain regulation

OECD defines due diligence as “an on-going, proactive and reactive process through which companies can ensure that they respect human rights and do not contribute to conflict”. Through this process, “companies can identify, prevent, mitigate and account for how they address their actual and potential adverse impacts as an integral part of business decision-making and risk management systems”. Its Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (2016) goes on to say that “due diligence can help companies ensure they observe the principles of international law and comply with domestic laws, including those governing the illicit trade in minerals and United Nations sanctions”. US and EU conflict minerals legislation aims to break the link between minerals and conflict financing. As formulated in Dodd Frank Section 1502 for instance, the regulation aims to “further the humanitarian goal of ending the extremely violent conflict in the DRC”. The EU regulation aims to “stop conflict minerals from being exported to the EU” and “mine workers from being abused”. Contrary to Dodd Frank, which focuses on DRC and neighbouring countries, the EU regulation applies to all conflict-affected or high-risk areas.

Practical guidelines on how to carry out due diligence in mineral supply chains are set out in the widely used but voluntary OECD Due Diligence Guidance. Although companies are responsible for their own due diligence, mineral traceability and due diligence programmes (such as ITSCI or Better Sourcing Program) can help them comply with these legislations. They typically provide supply chain information, monitor standards and help private companies identify and act upon risks. In addition, certification programmes (such as the Regional Certification Mechanism of the International Conference on the Great Lakes Region, the Chain-of-Custody Standard of the Responsible Jewellery Council or the Responsible Minerals Assurance Process of the Responsible Minerals Initiative) can help certify that private actors comply with specific standards. Several of these programmes have been set up by non-state (private or non-profit) organizations.

Following Tusikov (2017) we define non-state regulation as “non-state actors making, implementing and/or enforcing rules and standards”. In the case of mandatory due diligence, mineral buying companies have to monitor their suppliers. They must identify, assess and act upon risks (through mitigation and/or remedy) and report about actions taken. By making supply chain actors monitor each other, “the government outsources [regulation] to regulated entities themselves, which further outsource to private parties (e.g., industry groups and consulting firms) as well as suppliers who are regulating the tiers below them” as Sarfaty (2015) puts it. She further raises that this regulatory outsourcing “raises accountability concerns when private actors are performing functions that are fundamentally public”.

Answerable versus accountable

In this context of supply chain regulation being increasingly outsourced to non-state actors, we investigate whether and under what conditions non-state actors can hold private supply chain actors to account. So far, the literature on non-state supply chain regulation has heavily focused on transparency. Scholars such as Gardner et al. (2019) rightly argue that transparency of information is important for increasing compliance with relevant public regulations. However, it is not sufficient to comply with the regulations’ objectives (see Sarfaty, 2015). For instance, the Dodd-Frank regulation requires companies to provide information on their supply chains, but it does not require companies to stop or suspend sourcing from a mine where human rights violations were detected (Partzsch and Vlaskamp, 2016). The rationale is that consumer pressure instigates compliance. However, this rationale does not necessarily work out as such in practice (Kim and Davis, 2016).

Transparency can only be a starting point for accountability. Accountability is defined as “the relationship between an actor and a forum, in which the actor has an obligation to explain and justify his or her conduct, the forum can pose questions and pass judgment, and the actor may face consequences” (Bovens, 2007). In the context of our study, accountability can be understood as a private upstream supply chain actor (for instance a minerals exporter) answering for its actions to a non-state actor to whom regulation has been outsourced (for instance a non-profit organization implementing a due diligence programme) and facing the potential consequences of its actions (sanctions by the due diligence programme, such as suspension or expulsion as a member).

We argue that the possibility of sanctions (as a consequence of the private actor’s actions or lack thereof) is what differentiates being answerable (without consequences) from being held to account (with consequences). The availability of adequate information (for instance regarding supply chain risks) does not automatically prompt stakeholders to change their actions. In the absence of transnational jurisdiction for these matters, we investigate the potential of non-state supply chain regulation.

Case study: ITSCI in Rwanda

We study the first and most widely used due diligence and traceability programme for minerals, focusing on 3T (tin, tungsten, tantalum): ITSCI. ITSCI was formalized in 2011, growing out of the ITRI (now ITA) Working Group formed in 2008 – predating US and EU conflict minerals legislation. ITSCI’s purpose is to “create responsible mineral supply chains that avoid contributing to conflict, human rights abuses, or other risks such as bribery”. The programme “supports member companies to implement due diligence by working with governments and civil society and providing expert field, data, risk management and auditing teams”. ITSCI focuses on reporting and managing risks. It notes that “in the years between 2011 and 2016 ITSCI recorded and monitored 3,063 individual incidents across four countries which related to risks of support to armed groups, human rights abuses, fraud, corruption, lack of traceability and other issues which relate to the OECD Due Diligence Guidance Annex II.” According to an OECD evaluation that was concluded in 2018, ITSCI standards are fully aligned with the OECD Guidance.

Piloted in the DRC in 2010, the programme now monitors over 1800 mining sites in Burundi, DRC, Rwanda and Uganda. These mines have been identified and checked, and “if conditions are acceptable the sites are integrated into the traceability and monitoring system”. Traceability is then implemented by the respective government agents. In Rwanda the programme has the highest number of monitored sites and the highest monthly mineral production (on average) in comparison to Burundi, Uganda and individual provinces in the DRC. Membership is “available to miners (artisanal co-operatives, small or large-scale), local traders or exporters from the country of mineral origin, international concentrate traders, mineral re-processors, smelters, refiners as well as any company associated with the upstream mineral trade such as mineral transport and mineral assay companies”. Prospective members should commit to due diligence, hold all relevant legal documents, and provide adequate background information on the company. According to the latest membership list (October 2020) there are 25 upstream companies currently participating as full members in Rwanda.

The ITSCI programme is governed by the industry associations ITA and T.I.C., and assisted by a London (St. Albans)-based secretariat. Previously, some concerns have been raised about the lack of “involvement of external stakeholders in the development and oversight of due diligence, reporting and auditing activities of the programme”. The NGO Pact assists with the programme implementation in Rwanda. ITSCI holds Memoranda of Understanding with partner governments, which assist with traceability. In Rwanda, for instance, the Rwanda Mines, Petroleum and Gas Board (RMB) is responsible for mineral tagging and its traceability officers are trained by ITSCI.

Method

Our study included a three-month research stay in Rwanda, where the first author has interviewed 75 respondents in semi-structured interviews. Respondents were purposively sampled to represent a wide range of sectors and to have first-hand experience working or having worked with the ITSCI programme. For example, interviews were conducted with representatives of ten active full members (membership status at the time of the field research), two former members who had withdrawn from the programme, six former members who had been expelled, and one with a provisional member. In total, 32 respondents working for 19 active or former members participated. Twenty members of three cooperatives were interviewed. The remaining respondents represented, among others, local and international civil society, local advocacy organizations, independent auditors, consultants and donors.

ITSCI appointed Pact (ITSCI’s field operator) as the local point of contact for the ITSCI programme. Staff at Pact has been interviewed. After publishing a first version of the Analysis & Policy Brief of the research, ITSCI provided feedback, which was taken into account for an updated version of this Brief. Interviews were fully transcribed (for those who consented to audio-recording) and coded using NVivo 12 software. Our analysis relies on these interviews, as well as on documents obtained from respondents, online sources, and field observations, all of which have been carefully triangulated. The study focuses on implementation in Rwanda and does not consider the full supply chain.

Traceability

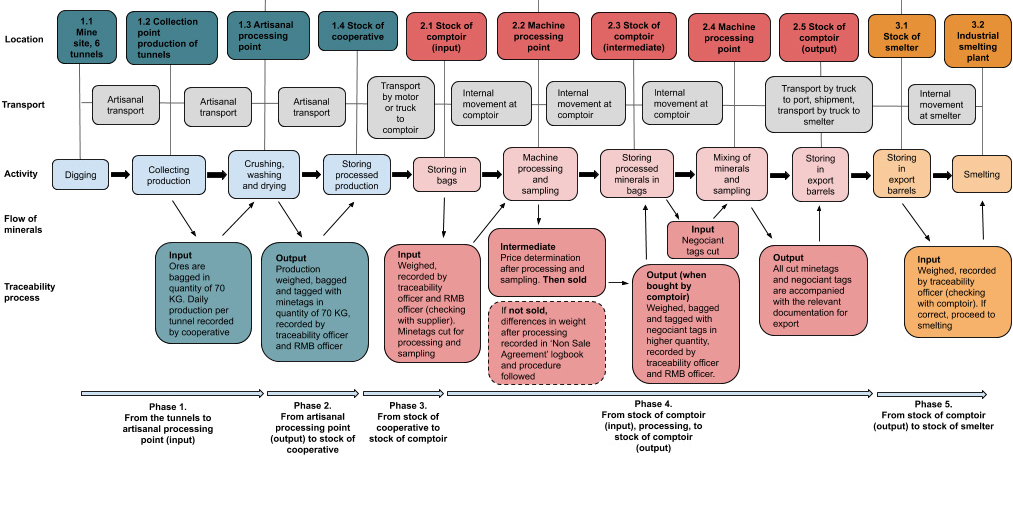

ITSCI provides a traceability system that uses tags and manual logbooks to track the journey of the minerals from the mine site to the smelter (see figure 1). Let’s look at a model example to illustrate the traceability process – note that many variations exist on the ground and reality is more complex than the stylized example suggests (figure 1, based on our interviews and observations). In this example the journey starts at the mine, where a cooperative mines the raw ore and carries out the initial processing. The ore is manually crushed and panned, after which it is cleaned and separated. Then the production is spread out on the ground to dry in the sun. When dry, the ore is cleaned, manually separated and put in bags of maximum 70 kilogrammes, to be manually transported. RMB mineral field officers weigh the bags and provide a tag that has been issued by ITSCI via the local Pact office to a RMB district office. They collaborate with traceability officers who work for the respective cooperatives (cooperatives’ or companies’ own staff). The information is independently recorded by the cooperative and the RMB in separate logbooks, which are shared with Pact. The minerals are transported to the comptoir (export office). At this point the bags are weighed and recorded again by a traceability officer working at the comptoir, in collaboration with a RMB Mineral Field Officer who must ensure the information is accurate. The tags of the bags are cut and the minerals are further processed, tagged with a négociant tag and sold to the comptoir if the price is agreed upon.

The data collected on the paper datasheets are entered into the computer at the local Pact office and then sent to the London-based data centre that manages the database for entry, assessment and validation, while RMB also receives a copy of the logbooks. Pact stated that the Secretariat is currently in the process of digitalizing the data collection system and they are training the 97 RMB field officers to enter data using a tablet. ITSCI has communicated that it is migrating to electronic data capture using a mobile app (ITSCI feedback, 30 July 2020).

Monitoring: ITSCI system

Seven ITSCI field officers have been assigned to 7 ITSCI working zones in Rwanda. As from 2018, RMB field officers have also been deployed to the district level “in order to better track procedural irregularities”. The most recent status report (Q3 of 2020) mentions that the ITSCI programme covers 990 sites,194 of which were active at the time of the report. According to ITSCI, monitoring is more frequent in sites with higher risks (ITSCI feedback, 30 July 2020). RMB Mineral Field Officers who are posted at processing and exporter level receive additional support from ITSCI “to correct errors or mistakes in data collection or general procedures as appropriate, and to provide refresher training or coaching sessions as needed” (Pact feedback, 26 August 2020). ITSCI provides regular training to RMB Mineral Field Officers (currently 97 in total) as well as to companies. ITSCI reports that in 2019, 442 joint ITSCI-RMB visits were conducted to different sites and 14 formal meetings were held with RMB officials. The programme furthermore communicates that the number of incident reports increases every year. An incident categorization system is in place, with ‘level 1’ being very serious incidents such as human rights violations, and ‘level 3’ being the least serious, such as a discrepancy in the recording of a tag number. ITSCI reports that when a level 1 incident is reported, the procedure provides that the ITSCI governance committee is informed within 24 hours and ITSCI members as well as the government are alerted within two weeks (ITSCI feedback, 30 July 2020). In its 2019 annual report ITSCI states that it opened “364 incidents in Rwanda, of which 321 incidents were related to the chain of custody, 14 to due diligence, 10 to security, and 19 to human rights. This represents an increase of 3% compared to 2018 when 355 incidents were recorded which is due to better monitoring.” This increase may indeed be due to better monitoring, but this is not necessarily the case (Pact Feedback, 26 August 2020) and needs to be further studied. As explained below, persisting incidents may result in sanctions being applied.

Monitoring challenges

Although ITSCI does provide “a range of resources to support companies with the risk assessment activities” (such as mine baseline assessments, monthly incident reports and a due diligence list naming mine sites or individual companies that have incidents raised against them), the 2018 OECD study concluded that “there is scope for improvement in how ITSCI engages with companies to encourage greater and more meaningful use of the tools and data made available to them”. The same study points to the “limited ratio of ITSCI audits compared to ITSCI membership (5 audits for 159 members in 2016)”, which “limits the current effectiveness of this as a means of driving implementation of ITSCI’s requirements for companies”. ITSCI has challenged this conclusion since upstream (beyond smelter) audits are not required by OECD and continuous monitoring on the ground is more effective than auditing.

Audits in Rwanda (not mandatory as per OECD Guidance) are carried out by the independent auditor Synergy Global. The auditor stated that the initial plan was to have one wave of audits every 18 months as a modus operandi. However, the last audits of the full members (exporters) in Rwanda were conducted in 2017 (for which summaries have been made public only in 2020 – Synergy Global also confirmed in an interview they had new audits planned for 2020), but to what extent these have been carried out (and to what extent this may be Covid-related) remains unclear. Five full members listed in the 2020 membership list became a member after 2017, meaning they have not yet been audited. One of our informants additionally claimed not to be aware of any audits, despite having been an active full member since before 2017.

Despite the efforts mentioned above, several respondents have highlighted monitoring challenges at the level of the mining sites. While some talked about challenges and difficulties faced by individual RMB Mineral Field Officers, at least five others (among which active and expelled members, and cooperatives) said that several RMB Mineral Field Officers appear to lack sufficient knowledge of the geological context, as well as the technological tools to do a thorough credibility check on the information on the tags, such as whether the minerals have really been sourced in a particular mine. In its feedback, ITSCI countered this statement by saying that geological data are important but not sufficient and that the consistent presence of RMB Mineral Field Officers at their assigned mines is the critical success factor (ITSCI feedback, 30 July 2020).

Regarding the accessibility of information, the 2018 OECD study concluded that “a significant amount of information is publicly available on the ITSCI website, including on member companies, risks and annual reports, albeit not always in a particularly accessible format and not always in a timely manner”. It should be noted that some commercially sensitive information, such as on production levels, must not be made public according to the OECD Guidance. It is true that the ITSCI website provides a lot of information. At the time of our research (October 2020), available incident summaries for Rwanda went up to June 2019 (according to ITSCI procedures incidents may remain open for up to 6 months while the information is being verified and/or acted upon), the latest Governance Assessment dated from 2013 and the last Annual Field Reports dated from 2018 (the 2019 report has been made available in the meantime).

Although ITSCI provides monthly incident summaries to its members, respondents from active members and former members told us that information flows between Pact, the ITSCI data team and the members are not optimal in their view. They complained, for instance, that information does not flow quickly enough, and that members do not have access at all times to information regarding their own supply chain as information passes through the Secretariat. It is reasonable to conclude that ITSCI does provide a large amount of information to both the upstream stakeholders and the public – and in this sense goes beyond what is expected by OECD -, but that challenges remain regarding the access to and timeliness of information.

Finally, challenges remain regarding the risk of minerals from non-ITSCI sites entering the ITSCI system. In its most recent report the UN Group of Experts writes that “minerals produced at mine sites covered by the International Tin Supply Chain Initiative scheme were sometimes tagged at a distance from the mine site of production, posing a risk of contamination”. In the 2020 report, the Group identified this risk across DRC’s North and South Kivu provinces (as they have done throughout several of their yearly reports since 2010, for ITSCI as well as for other traceability programmes), but they previously also did in Rwanda (such as in the 2015 report). The risk has been attributed to the fraudulent use of ITSCI tags by government agents (as stated by ITA in annex 47 of the 2020 report and by OECD in its 2018 report).

During our research in Rwanda, several respondents confirmed that this risk is still present in the country. A first indication is the discrepancy, noted by an exporter, between real and recorded production in some of Rwanda’s mines. The exporter said: “He is trading, he is coming with tags and I see that this mine that they have visited two times, there is nobody. But they still get tags, and they still come to sell”. He explained that minerals enter the ITSCI system at the production stage (phase 1 in Figure 1), as this is easier than to enter those minerals into the system at the stage of export (where the production always arrives with tags). The exporter further added exporters have no incentive to declare such incidents as they would “lose their supply”. Mining Technology reported that the lack of detailed information about production capacity “makes it hard to verify if the number of tags used correspond to the estimated production for each mine”. The discrepancy between real and recorded production in Rwanda has been previously explained by minerals from DRC being smuggled into Rwanda, where they are tagged and exported as Rwandan production (UN Group of Experts reports[1]).

Secondly, there is a risk of fraudulent use or sale of tags. ITSCI acknowledges

this risk, but adds that controls are continuously adapted and improved to

minimize this risk. ITSCI also points out that they are not the only actor

responsible for monitoring, and that they follow up on such incidents together

with RMB, local authorities, the Rwanda Mining Association and the Federation

of Mining Cooperatives (ITSCI feedback, 30 July 2020). ITSCI further stresses

that the programme is not responsible

for due diligence (as companies remain responsible for their own due diligence),

neither for the tagging (as local government agents are responsible for the

tagging) (ITSCI Feedback, 30 July 2020). Respondents in two interviews confirmed that the fraudulent sale of tags

is indeed more difficult nowadays: the system of collecting and delivering back

excess tags has been tightened. However, respondents in four other interviews

(with one expelled, one withdrawn and two active members) stated that (excess)

tags are still being sold or tags are provided in a fraudulent way.

In their response, RMB states that according to their procedures, ITSCI and RMB jointly determine the quantity of tags a stakeholder may use on a weekly basis during a baseline assessment. This baseline assessment is then updated accordingly during regular inspection visits in the field to prevent mineral tagging incidents. Changes in production level or operations will therefore be detected. The RMB officer responsible for the tagging must, according to the procedure, tag minerals from licensed and certified mines, and is expected to report on any relevant changes in observed circumstances or challenges regarding the traceability system in their respective working area. The RMB Mineral Field Officers are further cooperating with local administration officials, who in turn share information on any suspended or unlicensed mining activities. Regarding the procedures put in place, the RMB finds it therefore difficult to relate to the statements made by informants on non-ITSCI minerals entering the ITSCI system to their observed reality (RMB Feedback, 26 October 2020).

Sanctions

In case of persisting incidents, the ITSCI governance committee (one ITA representative and one T.I.C. representative) may decide to suspend, and eventually expel members. As a first step, ITSCI field officers would formulate a warning and recommendations for improvement. However, if incidents persist, sanctions may be imposed. We found that these sanctions are effective and that ITSCI can hold private actors to account, as the latter are required to answer to ITSCI and debate the acquired information with ITSCI. Refusal to do so can lead to suspension or expulsion. The membership list (October 2020) shows 3 suspended and 29 expelled members (5 of which have been expelled since September 2020) in Rwanda.

Respondents have said that suspension or expulsion from the programme may severely affect the private actors’ access to international markets. Just like US and EU regulations require companies to provide proof of the origins of the minerals they buy, exporting minerals without a certificate of origin is illegal in Rwanda. The ITSCI programme helps companies in this process. As stated above it is currently the most widely adopted programme for 3T in the African Great Lakes Region, although companies can perform due diligence in many possible ways, with or without the assistance of external due diligence programmes.

Respondents (including an active, expelled and withdrawn member and well-informed consultants) told us that companies are reluctant to pull out of the ITSCI programme: they fear they will lose access to the international market because major smelters work with ITSCI (see the website of ITA members Malaysia Smelter Corporation or Thaisarco, see also Rwandan New Times and Reuters). The reason given by two consultants is that for pragmatic reasons, some smelters prefer the ITSCI system as they fear high transaction costs when having to switch to a new system. Furthermore, four informants (three of which have extensive experience in the downstream sector) stated independently from each other that ITSCI is able to influence the purchasing decisions of some mineral buyers. Respondents also said larger exporters may find it easier to withdraw or join a different due diligence programme, as they can make deals with buyers themselves, but for smaller companies it is difficult.

In this context, previous academic research (Cuvelier et al, Vogel , Vogel et al., Vogel and Radley, Sarfaty) and media (Rwandan New Times, Reuters, Mining Technology) have criticized ITSCI’s dominant position. In an article that was published on The Washington Post website in 2014, Vogel and Radley conclude on the basis of their field research in the DRC that “the industry-led traceability scheme currently serves more as an artificial price-control mechanism and a monopolization tool: the levy ITRI demands for each ton of tin is directly subtracted from the official selling price […]. The net effect is that Congolese miners must pay the international tin industry for the right to sell their minerals with a tag that implies – but does not necessarily achieve – conflict-free status”. More recently (2019) the RMB has declared it is trying to “attract other competing instruments” because “the cost of traceability and due diligence must be reduced to make it affordable and fair”. Our respondents, including active members, have similarly complained about the high costs they pay to the programme. Two respondents told us that ITSCI’s dominant position has made it very difficult for them to negotiate about the possibility of lowering levies. At least nine respondents, including a representative of a local advocacy group, exporters, consultants and the RMB, expressed the concern that they find it difficult to understand how the ITSCI revenue is invested back into Rwanda. ITSCI responded that their expenditures are stated on their website. This however does not detail operation costs per country, neither does it specify the break-down of the expenses for ‘field operations’.

Conclusions & future research

Supply chain regulation is increasingly outsourced to non-state actors, which raises accountability questions. In the case we describe, companies are responsible for conducting due diligence, but they heavily rely on a traceability and due diligence programme that provides supply chain information, monitors standards and helps private companies identify and act upon risks. To hold private companies to account in such a context, we argue, there are four important conditions. Firstly, the due diligence programme should provide clear and timely information to all stakeholders. Secondly, high-quality and frequent monitoring should be ensured. Both elements are important to make companies answerable. Thirdly, to make them accountable, there should be a possibility of imposing credible sanctions. For instance, when non-compliant companies face difficulties finding a buyer for their products, this constitutes a credible sanction. Fourthly, it is important that the governance of the due diligence programme acts in the public interest. In this sense some concerns have been raised about ITSCI’s organizational structure. It is reasonable to conclude that the ITSCI programme does meet the third condition on sanctions, but that it faces a number of challenges with respect to the first, second and fourth condition.

Finally, we argue that due diligence should be considered as an instrument to achieve an impact (desired change), not an end in itself. As stated in the introduction, the US and EU regulations have been set up with the aim to break the link between minerals exploitation/trade and conflict/human rights abuses. ITSCI states on its website that the programme’s purpose is “to create responsible mineral supply chains that avoid contributing to conflict, human rights abuses, or other risks such as bribery”.

However, the positive effect of due diligence on human rights or conflict cannot simply be assumed. Companies may be 100% compliant with due diligence requirements, but not contribute to the desired policy goal (desired change). In a 2019 article Landau draws attention to the risk of “cosmetic compliance”. This means that companies formally comply with due diligence by adopting all necessary “internal policies and compliance structures”, but fail to address “the question of how to regulate for meaningful human rights due diligence that is capable of achieving the public policy goals to which it is directed” (for a recent comprehensive report on the shortcomings of transnational voluntary regulation in protecting human rights, see MSI Integrity).

It is reasonable to conclude that there is indeed a risk of cosmetic compliance in the case of mineral supply chain due diligence. A recent IPIS study in the DRC concluded that the positive effect of due diligence on human rights compliance is still unclear, and that more research is needed to verify the assumed causal relations (the study found that participation in due diligence programmes correlates with better human rights outcomes, but this may well be due to the fact that such programmes are implemented in more stable and accessible areas). This also joins previous academic studies on the impact of Dodd-Frank in the DRC, among others by IOB colleagues, which have found that it has not reduced conflict or improved livelihoods. More independent research is needed to follow-up on these issues in the medium and the long run.

Acknowledgements

The field research for this study would not have been possible without VLIR-UOS (Flemish Interuniversity Council) and the University of Antwerp. Above all, our sincere gratitude goes out to all respondents for their useful insights and helpful advice.

This work was supported by the Fonds Wetenschappelijk Onderzoek – Vlaanderen (FWO) and the Fonds de la Recherche Scientifique – FNRS under EOS Project No G0G4318N.

Authors

Hester Postma, Institute of Development Policy, University of Antwerp.

Dr. Sara Geenen, Assistant Professor, Institute of Development Policy, University of Antwerp.

[1] UN Group of Experts final reports 2010 p.78, 2011 p.6, 2012 p.4 and 43, 2013 p.40, 2014 p.45, 2015 p.34, 2016 p.26, 2017 p.18, 2019 p.31.